New Pallet Wrapping Machines

- For short run wrapping

- Designed to wrap long profiles, such as cooper tubing to doors,

- Manually operated

- In line turn table pallet wrapper

- Fits into conveyor system

- Eliminates labour from wrapping pallets

- Fast and efficient.

- Low cost automated packing line

- Pallet does not rotate, ideal for

- Unstable or heavy loads

- Top sheet applied without stopping machine

- Very fast automatic packing line

- Pallet does not rotate, ideal for

- Unstable or heavy loads

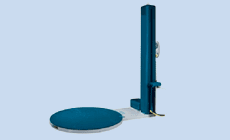

- Entry level pallet wrapper

- Guarantees well wrapped loads that will not slip off the pallet

- Ideal for low volume users

- Good general work horse

- Will wrap almost any style of pallet load

- 2000 kgs turn table

- Well-built sturdy machine

- Save money, convert it to a power stretch machine as demand increases

- (saves buying a new machine)

- Best range of programs for wrapping any type of pallet load

- Guarantees well wrapped loads that will not slip off the pallet

- Improves working conditions

- Comply with health & safety regulations

- Suitable for medium to high volume users

- Reliable, strong good for heavy pallets

- Wide range of wrapping programs, security locked

- Very economic wrapping costs

- Suitable for medium to high volume users

- Reliable, strong. security locked controls

- Unique low turn table max weight 1200 kgs

- Alternative to pit frame, easy loading. small space

About Our Pallet Wrapping Machines

Focus Packaging offers a full range of pallet wrapping machines – often referred to as shrink wrap machines – to suit every individual business need; capable of wrapping the following:

- long extruded profiles

- a polo mint, style product (hollow in the middle), be it round or square

- normal sized pallets

- loads that are too large or heavy to spin on a normal turntable pallet wrapper

Our turn table shrink wrap machines can be integrated into a conveyor production line, while our ring wrappers and overhead arm wrappers will also be integrated, but straddle it.

Our Alpha range of pallet wrap machines contains a solution for any quest.

The Widest Range of Shrink Wrap Machines Available Anywhere

All of our stretch wrap machines have the advantage of being a pedigree of time; i.e. having been continuously developed over the years to be reliable, robust in construction and versatile enough to wrap any load the best in their category. They produce very cost-efficient wrapping solutions every time.

With a service contract and our field servicing facility, our machines will give you years of trouble-free use.

The range starts from the manual Walk A Bout and the humble Alpha 104 – designed to wrap the lowest number of pallets mechanically on a daily basis – to the sophisticated Alpha G Ring wrapper, which straddles a production line that carries pallets too heavy to be rotated, or just not suitable for rotation (such as mineral water).

However, it is often the Alpha Robot that draws the most attention. With its multitude of individual recordable programs, high power stretch ratio of 300% for stretching the film, and being totally mobile and capable of wrapping a pallet completely unaided, it is the most versatile piece of pallet wrapping technology available anywhere. Because of its mobility, this makes it a particularly practical and cost-effective pallet wrapping machine. It also eliminates the necessity of moving unwrapped pallet loads through the works to the static pallet wrapper. One charge hand can operate 2 or 3 robots simultaneously in the same packing area.

Modern Turntable Pallet Wrapping Machines

The most numerous types of pallet wrappers are the individual turntable wrappers, found in most business premises. They are either mechanical brake or power stretch machines. The older types of power stretch will only stretch your film by 100%. The newer types of pallet wrappers will stretch your film by 300 to 400%. This is how you save real money on wrapping costs, by stretching the film further.

A 100% stretch wrapper will offer 2 meters of film to wrap your pallet, a 300% stretch wrapper will offer 4 meters of film to wrap your pallet. That’s 50% saving on your film costs. So a £10,000 spend on a pallet will reduce to £5000. We offer you free advice and guidance here and will also test your machine for performance.

Bespoke Pallet Wrapping Potential

To wrap unusual products like wooden mouldings, metal or plastic extrusions, metal tubing or laminate floors, we offer the manual or automatic Orbital Wrapper. Equally, should your product have no end or beginning – i.e. it’s polo-shaped like a rubber tyre, a coil of metal or flexible plastic tubing – our Artimas pallet wrapping systems have the solution for you.

Industry Applications

Pallet wrapping machines are essential across a variety of industries, significantly enhancing the efficiency and reliability of supply chains. In the manufacturing sector, these machines use pallet wrap to secure products for storage and shipping, ensuring they remain intact throughout the process. A stretch wrap machine is widely employed in the food and beverage industry to protect perishable goods from contamination and damage. The logistics and distribution sectors rely on stretch wrapping for stabilizing loads on pallets, which is critical for safe and efficient transportation. Plastic film used in these machines provides an economical and durable solution for wrapping pallets, offering superior protection. Pump trucks are often used in warehouses to move wrapped pallets, highlighting the importance of stretch film in facilitating smooth operations. The pharmaceutical industry also benefits from these machines by using them to securely package and transport sensitive medical supplies.

By integrating a pallet wrapper into their operations, companies across these industries can achieve better load stability, reduced damage rates, and improved overall efficiency. Additionally, innovations such as compressed air assist in the wrapping process, ensuring tight and secure packaging, which is vital for maintaining product integrity and optimizing supply chain performance.

Focus Packaging Also Provides:

- a service where we check your pallet wrapper on site, relating to power stretching abilities, as well as offering comparative pricing for wrapping your pallets.

- a breakdown repair and service facility across England, Scotland and Wales.

- renovated, serviced and repainted pre-used pallet wrappers; register with us for available machines.

Contact Focus Packaging Today

To enquire about one of our high-quality shrink wrap machines or pallet wrapping systems, don’t hesitate to get in touch. You can contact our team on 0333 123 6666, where we are always eager to answer any questions you may have or to address your pallet wrapping machinery project.